Essential gestures applied in the service of exceptional silverwork.

Planishing

Based on the design, I begin cutting the silver plate in desired dimensions. Then I choose a technique.

For flatware, I stretch the metal over a curved surface and hammer it with mallets of all shapes and sizes in a circular pattern from the outside in. This is the planishing technique.

For an oval-shaped piece, I place the metal on a head and hammer from the center outwards. This is the hammering technique.

Eric Popineau,

Puiforcat workshop’s master planisher,

awarded the prestigious title of Chevalier of the French Order of Arts and Letters.

Spinning

To shape tumblers, ewers, coffee pots and other volumunous pieces, we use a spinning lathe.

I place the silver plate on a wooden mandrel that turns horizontally and determines the curved form. I spin the material with a tool called a ‘spoon,’ to give shape to the object. Several passes are often needed for the piece to take on the desired form.

Cold-worked silver can shrink, so forging is often necessary to soften the metal. This step is called "annealing".

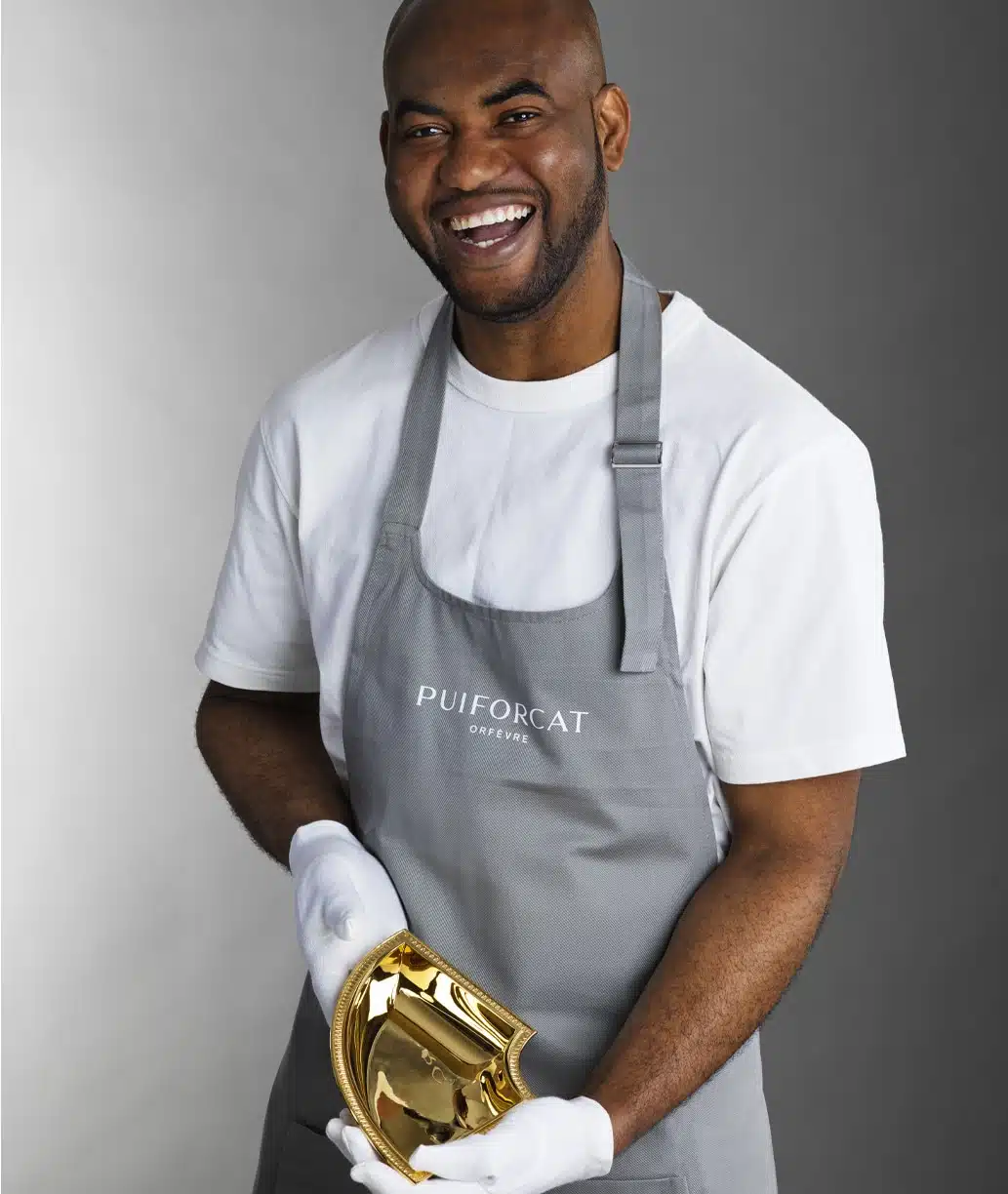

Mickaël,

repoussé craftsman at the Puiforcat workshop

Silversmithing

My job is to assemble the pieces.

I put together the different parts of the object using ingenious mechanisms, signatures of the House. Puiforcat’s savoir-faire is unique in our ability to integrate cover hinges into the body of the piece, making them invisible.

I also use the brazing technique to adorn the object with fixtures, moldings, knobs, spouts, hinges, feet or other embellishments.

Agathe,

silversmith at the Puiforcat workshop

Chasing

Chasing involves decorating the metal piece without removing any material.

First, I draw the motif on the piece using a tracing paper and place the object on a stable base.

Then, I begin to print the motif by embossing the metal using small steel chisels called "chasing tools".

Nathalie,

chaser at the Puiforcat workshop

Etching

Etching is a form of decoration that cuts into the metal extracting thin shavings.

Using a needle or bruin, I reproduce fine hatch marks, curves, dotted lines: a design, a number or a coat of arms. Any motif is achievable using different techniques.

The ‘guilloché’ process, for example, adorns the metal surface with infinitely variable repetitive geometric designs and patterns, such as crosshatches, stary grid patterns, wavy lines or barley grain designs.

Blanche,

engraver at the Puiforcat workshop

Finishing stages

Every unnecessary relief on the piece must disappear.

I eliminate even the most microscopic irregularities using sanding brushes and buffing wheels before finishing with a soft flannel cloth. This is the buffing technique.

Then I bring out the material’s luster and create a ‘mirror-polish’ finish using polishing brushes that give exceptional shine to the object.This is the laststage, the polishing.

Hilaire,

polisher at the Puiforcat workshop